Well, it had to happen, its winter, its cold (obviously); the solar panel is in a fixed position and the sun is low in the sky, so we're just not getting the power or being able to store a sufficient amount to make this all work. The system will run for a couple of days, but then it dies in interesting and random ways, random lock-up's failures to open the door, etc. The batteries are just exhausted.

I need to improve the power generation and I'm not going to tether it from the house. Its also clear that I am not going to get that designed, built and installed during the winter months, its just too cold.

So, a couple of 4mm jacks are installed on a bypass hook-up that takes the solar charge controller out of circuit, we can then use the car battery charger on "bike" mode (lower charge current) and with a large rubber coated, heavy grade solar panel cable that was spare, lash it up to allow charging. The negative to this is that we need a small window open and its not ideal from a heat loss perspective in the house, but we only need this every 4-5 days, and we can close the curtains to reduce heat loss, so its tolerable. The other option is to find a used car battery with a higher AH rating. We don't need the cold-cranking-Amps rating that car batteries have, just more staying power.

We need a solution that can turn the panel to follow the sun, but what to use ?

After a bit of a think and a Google, I come to the conclusion that radio hams use antenna rotators to move their aerials, so I can probably do the same with a solar panel. However, finding a good one turns out to be difficult, particularly in the UK.

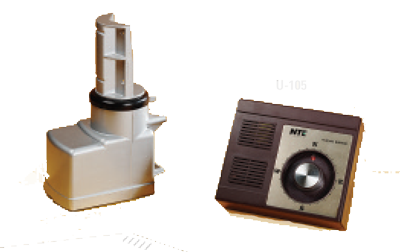

The American made NTE U-105 keeps coming up along with the TB-105 additional support bearing, but as these are American units, that means imports and 110VAC power sources which I've not got, which in turn means borrowing my Dad's auto-transformer and Variac to test things and find out how they work, this also means imperial measurements and threads.

Above is the rotator, the control unit which i won't need after 10 minutes with a screwdriver. The bearing gives 2 fixing points, which I'm going to need given the large surface area of the solar panel.

Its also clear that I'll need to produce a driver, buts its a motor in a box, how hard can it be ? According to my dad, who has an old UK model they are 1960's technology - gearboxes, switches and motors integrating that should be a doddle.

So, I order and get a roll of cable free too - nice, so its time to wait and think about how to do this now.