Lead Acid batteries are supposed to be charged at a precise voltage and a maximum current, this equates to 2.35 volts per cell and a current of no more than 1/10 of the AH rating of the battery. Given we have a 6 cell battery rated at 12AH, we should charge at no more than 14.1 Volts and no more than 1.2 Amps. The Battery University is a wealth of information on this subject and with the technology being invented in 1859 by Gaston Planté, there is loads of information available on their characteristics. There are even cheap IC's that ensure the right charge conditions are met through the charging process.

Having considered the numbers and read the solar panels data sheet and the Battery University site, I realised that the single battery probably wasn't going to provide enough power, since the charge time is governed by the sun and whilst the sun is out a lot in the summer, its only there in a lower power during the winter and for a shorter period, so I need to grab what power I can when its available. A general rule of thumb is that 1/5 of the summer power is available in the winter months through the same period of time. I also found out that Lead Acid batteries don't like the cold and their storage capacity can be 50% of the summer capacity and that they must not be frozen at all or they permanently fail. In addition, they don't like being too hot either, since this reduces their lifespan, so we need to put them out of direct us light too.

I therefore got a second 12AH leisure battery of the same type, since another rule of charging is that they need to be the same type of battery - i.e. an identical number of cells and AH rating and therefore have an identical set of characteristics.

I started testing the charge control and sensing module, and early during those tests, I noticed that the lead acid batteries were not happy. Very quickly after the power was applied, you could hear the electrolyte in the battery boiling. This is really bad for a lead acid battery and particularly a sealed one, where there is nowhere for the hydrogen gas that is liberated to go, so you end up with a dead battery and a potentially explosive situation due to the increased pressure, but what was causing this ??

After a bit of checking, it became apparent that the charge controller wasn't doing its job, it was putting the full voltage from the solar panel straight across the 12V battery, thats around 18V from the theoretical 21V maximum and its way beyond what the battery expects, so the unit must be faulty. A replacement unit was obtained from Maplin - I'll worry about the RMA later on once I know whats going on.

I get home with the new unit (and a second battery) and give it a try and its EXACTLY THE SAME !!, surely two units can't be faulty ? So, I talk to technical support at Kemo, who proclaim that the solar panel is too big for the batteries. Hang on a minute, this product is a charge controller, its supposed to do what its name says, "control the charge" and anyhow, I can't use a smaller panel, since I need to account for the worst case of mid winter when I have that 1/5 I get in the summer, this is why you need a controller in the first place - to limit the power delivered to the batteries.

For fun, I tried the "consultants" advice and increased the battery load by using both in parallel (24AH worth) and it indeed does not boil as much - since that's half the power to each battery now, but the fact remains that its not controlling the charge at all, its just dumping all the power into the batteries. In my view, these units are just plain dangerous and have been returned for refund. Exploding Lead Acid Batteries are not the sort of thing you want to end up with, so I suggest you steer clear of these units if you are doing solar projects.

For info, Kemo's 'fix' to this issue was to mandate a minimum battery size on the next data sheet. Kemo you need to fix your product. Please and learn about lead acid battery chemistry and look at other peoples charge controllers for ideas.

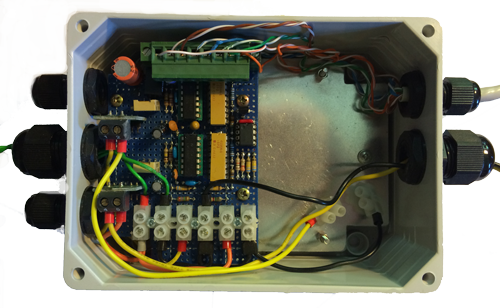

Either way, now I have a problem, there is a hole in my design and void in my box.

So I refer back to SunStore and see what they can do. I settle on a different brand of charge controller unit, however, the right unit is now far too big to go into the chassis, so its going to have to be external and therefore moisture proof, I order a EPSolar SeaStar Waterproof 10A, 12/24V charge controller that is rated at the same 10A as the Kemo unit, its just twice the price, but comes in a metal chassis.

On arrival, I connect up the new unit and what do you know, 14 volts on the batteries and they are happy and after a couple of hours the controller reports as fully charged - just as you would expect. I guess this is another case of your get what you pay for. This also demonstrates again that the Kemo product is defective as the only thing to change was the controller unit.

Now its all working, I decide to fit the Lead Acid batteries and I decide to mount them on a strong steel bracket and perspex shelf (as the batteries are heavy). This is under the nesting boxes, where they are outside and can therefore dissipate any Hydrogen gas created during charging, they are also protected from the rain. Secondly, they are in a relatively low risk place if they do fail and can easily be encased in several layers of bubble wrap to offer some protection against the frost and cold in the winter months and direct heating in the summer months. The result looks like a large cocoon has been created under the coop. I might have to reconsider the alternative option of a hole in the ground, which was previously rejected as it will fill up when it rains.

Anyhow, now we have power, we can make things work.